REVEALING THE TIME DEPENDENT TUBE DILATION IN ENTANGLED POLYMER BLENDS WITH NEUTRON SPIN ECHO COMBINED WITH DIELECTRIC SPECTROSCOPY AND RHEOLOGY

An open question on the dynamics of entangled polymers is how the topological constraints are released by mobile neighboring chains or, in other words, how the constraining tube is dilated. This work by members of the Polymers & Soft Matter group (in collaboration with Forschungszentrum Jülich, Germany and Institut Laue-Langevin, France) reports the direct microscopic observation of the time-dependent tube dilation in iso-frictional blends.

DOI: 10.1103/PhysRevLett.123.187802

The mechanical performance, industrial processing and other end use properties of polymeric materials are determined by their dynamics. Hence, it is important to fundamentally understand how the macromolecules move in the material, in particular in modern materials with increased complexity.

Nowadays, it is well accepted that the viscoelastic properties of high molecular weight polymer melts are controlled by entanglements: topological constraints imposed by mutually interpenetrating and uncrossable polymer chains. In the tube model for entangled chains, these constraints are represented by a tube that restricts the lateral motion of the polymer chain within its diameter leading to a reptation motion of the chain along the tube.

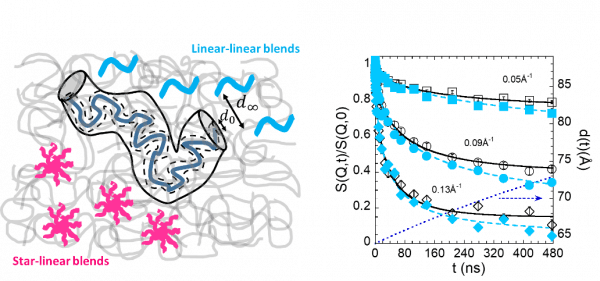

Left: Schematic representation of the tube dilation in linear-linear and star-linear blends. Right: Time evolution of the chain dynamic structure factor measured by NSE for the long chains in the pure matrix (black) and in the blends with short linear polymer (blue). The dotted line shows the increase of the tube diameter in the blend as the time increases.

However, the pure reptation model fails in real materials, which are polydisperse and most times multicomponent. In these cases other mechanisms compete with reptation, mainly, contour length fluctuations (CLF)—fluctuations of the length of the tube—and constraint release (CR) — probe relaxation driven by the motions of surrounding chains. CR becomes particularly important in polydisperse melts and binary blends, especially where long polymer chains are mixed with short additives of the same chemistry (iso-frictional blends) but sometimes of different polymer architecture. A simplified model of the many-body CR mechanism, called dynamic tube dilation (DTD), considers that CR leads to an increase with time of the tube diameter. The effective terminal tube dilation of the long chains in polymer blends can be determined by obtaining the long-time tube diameter from macroscopic techniques such as dielectric spectroscopy and rheology. However, these techniques cannot resolve the time evolution of the tube dilation. This work exploits the spatial and time resolution of neutron spin echo to directly probe the time-dependent tube dilation in model blends based on polyisoprene with different topologies. By combining NSE with rheology and dielectric spectroscopy, the characteristic time that governs tube dilation is identified as the terminal time of the additive. This finding will help elucidate the mechanism for constraint release and, thus, will facilitate the design of polymeric materials with the desired rheological properties.