Belite Cements and their Activation

Belite cements, BCs, containing mainly belite, alite and calcium aluminates, are currently used as low heat cements. These binders produce high amounts of C–S–H gel and have very good durability properties which are reviewed.

Additional advantages include: (i) lower limestone demand, with lower associated CO2 emissions; (ii) lower energy demand; (iii) lower kiln operating temperature, which means lowering CO2 and NOx emissions from fuel burning; and (iv) lower temperature increase at early hydration age. However, early-age strength developments are not competitive with those of Portland cements. Hence, to improve their early-age strength developments is a research priority known as activation. This enhancement can be attained by three compatible approaches: (i) chemical, (ii) physical; and (iii) admixture activations. The current research status for BCs activation is reviewed including: cost-effective element substitutions to stabilize high-temperature forms; fast cooling, milling and mild temperature hydration as physical activation; and the use of C–S–H seeds as admixture activation. After discussion of the resulting microstructures, a research outlook is exercised.

(In cement chemistry notation, C= CaO, S= SiO2, and H=H2O)

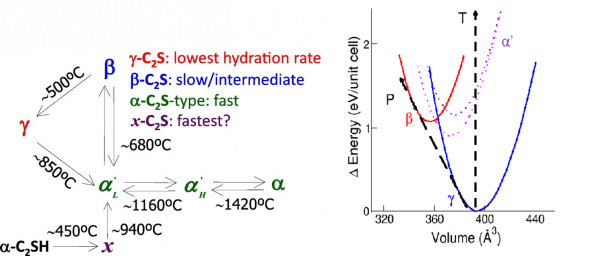

Fig. (Left) Polymorph relationships for stoichiometric Ca2SiO4. Qualitative hydration rate sequence is also shown. (Right) Scheme of the energies between polymorphs using data from Ref. [1]. Note that C2S polymorphs can be reached by temperature and pressure following a different order.